Product Overview

Unique Scheduling Solutions

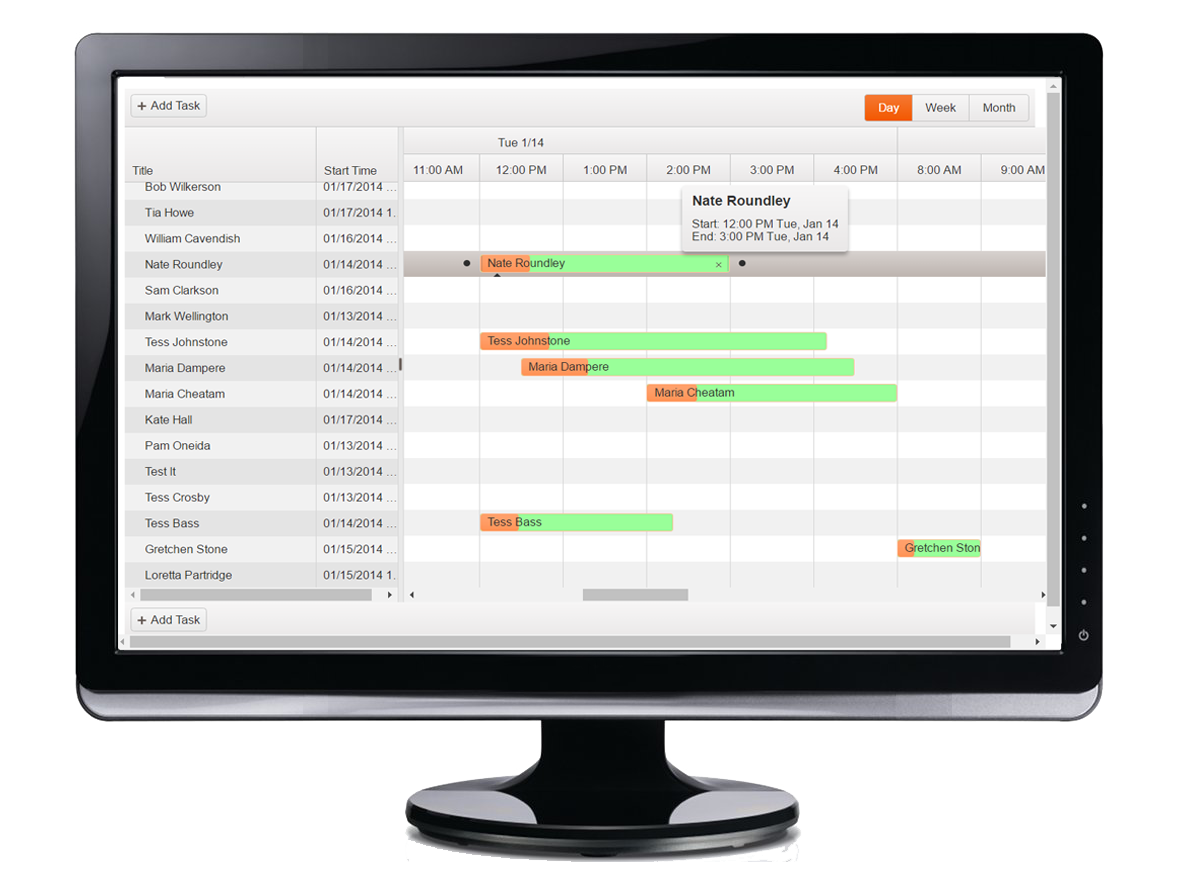

We are a software as a service (SAAS) company offering a cloud-based scheduling application. The product is unique because of its ability to handle activities requiring multiple resources over various intervals and in variable quantities. Availability of all resources can be time varying and can be limited. This makes the application ideal for environments that have several limited resources that are shared among multiple activities. Examples of these environments are manufacturing, health care facilities, hotels and event centers, movie and TV production, service industries, and educational institutions. The application is as essential to time-based operations planning as a spreadsheet is to financial planning. Although the scheduler is generic, domain peculiarities are easily accommodated.

The product is an easy-to-use adaptation of a scheduler built for NASA mission planning and for several fortune-500 manufacturing companies.

We are building a suite of demonstrations including an operating room scheduler for hospitals, a sports league team game scheduler, a hotel event planner and a manufacturing shop floor scheduler. Several others will follow from our user community.

The application is also well suited for materials planning, "what-if" scenario evaluation, for designing different operational configurations, and for environments where frequent rescheduling is the norm. Small users have a low-cost subscription option, and the application will scale to the largest operations. There are no limits on the number of activities to be scheduled, the number of resources required, or the time horizon being used. Resources can be defined as individuals or as pools with time varying availability profiles. No preset intervals (time buckets) are assumed.

Savings are derived from two sources. Less time spent by the human schedulers and more efficient use of scarce and expensive resources such as equipment, people, vehicles, or facilities.

Specifications

All the capabilities of an ENTERPRISE SCHEDULER at a fraction of the cost!

Unique Scheduling Solutions has built a special edition of its powerful award-winning scheduler just for manufacturers. Now you can get all the scheduling capabilities of a 6-figure installed system without the initial set-up hassles, recurring maintenance fees, or internal IT requirements.

Here’s list of the features specially adapted for manufacturers:

Production Tasks

Production tasks can use any number of machines, technicians, work centers, tools, other resources.

Easily Locate Tasks

Easy location of all tasks by work-order, customer, due date, machine usage, attributes, or any other tags the user supplies.

Multiple Objectives

Multiple objectives that can be blended based on user’s preference and operational practices.

Offsets & Overlaps

Schedule offsets and overlaps between production tasks.

Easy Schedule Maintenance

Easy revision to parts of schedules without disrupting more production tasks than necessary. Promotes easy schedule maintenance.

Wild Card Requirement

Schedule using specified requirement for any qualified machine, person, tool, other resource (wild-card resources) or specify a particular resource by name.

Over-use Prevention

Can enforce a maximum number of resource assignments in a specified time interval. Prevents over-use of critical resources.

Capacity Planning What-if

Enforce, Track, or ignore all capacity constraints. Perfect for Capacity Planning and What-If Scenarios.

Resources for Any Intervals

Production tasks can use resources for any intervals within the task. You can specify as many on-and-off usage intervals as desired, and even change the quantities required within the task. Example: a 4-hour task requires a machine for the first hour and last 2 hours, an inspector for hours 2-3 and an operator for the entire 4 hours.

Attributes on Any Resource

You can describe people by skill, machines by capacity, location, size, etc.

No Time Buckets

Times need not be specified in preset increments. Durations can be adjusted based on quantities required and run-rates.

Mass Editing

Mass editing of production tasks. Allows simultaneous changes to multiple activities.

Products & Routings

Input any number of Routings and Production Sequences.

Start & Finish Constraints

Earliest start and latest finish constraints on any or all work orders and production tasks. Includes separations and overlaps between tasks.

Display all Possibilities

Display of all scheduling possibilities (Feasible combinations of times and resources when a production task can be scheduled or re-scheduled).

Easy Schedule Maintenance

Easy revision to parts of schedules without disrupting more production tasks than necessary. Promotes easy schedule maintenance.

Available-to-Promise Date

An Order Processing Window that automatically calculates an “Available-to-Promise” date (ATP).

Multi-Level Planning

Individual and pooled resources support multi-level planning. High-level capacity planning using pooled resources. Execution-level planning using individual resources.

Fixed or Rolling Scheduling

Mass editing of production tasks. Allows simultaneous changes to multiple activities.

Prioritize Production

Priorities on production tasks or entire routings (999 levels).

Specified Dates

Specified dates when attributes will take effect. Example, attributes change as technicians are trained, machine capacities are upgraded, resources are moved, - - -.

Capacity Model

Time-varying initial resource availability profiles. The capacity model can change over time.

Routings & Bills-of-Material

Any number of Routings and Bills-of-material.

Attributes use "AND/ OR"

Attribute requirements can be combined with “AND” and “OR” logic. Example: I need a machine with capacity 5 tons AND a lift-height of 5 feet.

Long-run Production Tasks

Interruptible and non-interruptible activities (production tasks can be allowed or not allowed to flow around shift boundaries, weekends, holidays, - - -)

Easy Schedule Maintenance

Easy revision to parts of schedules without disrupting more production tasks than necessary. Promotes easy schedule maintenance.

Capacity Model

Time-varying initial resource availability profiles. The capacity model can change over time.

Easy Schedule Revisions

Seamless combinations of manual and automated scheduling modes. Designed to support easy schedule revision and planned vs actual synchronization.

Graphic Displays

Graphical and textual displays of all production resource assignments.

User Interface Display Includes:

Displays Filtered By Resource Type, Project ID, Routing Or Any Other Descriptor

Find all and only those activities affected by a difference between 'planned' and 'actual'

Find all successors to a delinquent activity

Find all downstream activities using the same resources as a delinquent activity

Find all activities in a given priority range

Find all activities in a given time interval

Easy rescheduling.