Product Overview

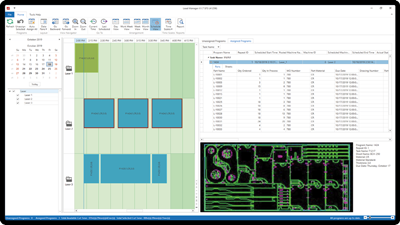

SigmaNEST

The World’s Most Advanced CAD/CAM Nesting Software SigmaNEST drives nearly every type of profile cutting, routing, or punching machine to produce premium quality parts while saving valuable material and manpower. SigmaNEST offers CAD integration, an intuitive interface, and local customer support, which sets the software apart and are all reasons why SigmaNEST is the industry leader with over 21,000 systems installed worldwide.

Specifications

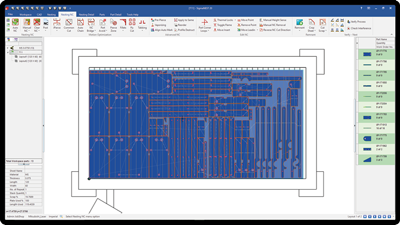

Intelligent Nesting

Advanced algorithms used in SigmaNEST software optimize material savings with using part rotation, mirroring, and more

Nesting strategies for complex machines account for hold downs, clamps, repositioning, bevel cutting, and secondary processes

Effortlessly nest parts for specialized operations and materials like right angle shear, drop door part ejection, and common line cutting

Automated choices for best sheet size and sheet priority

Powerful Inventory Management

Remnant Nesting promotes a First-In First-Out approach to help maintain lean inventory

Track inventory status and cost through integrated stock and remnant material database

Real-time sheet and heat number tracking

SigmaNEST integrates with exisiting ERP/MRP systems to ensure accurate sheet quantities

Easily identify customer consigned sheets or reserved inventory

Quickly search sheet, part, and work order lists

SigmaDEVELOP_GoreNest

Efficiency and Savings

Experience a variety of options to reduce pierces, save cutting time, and accurately cut your parts.

Consequently, this comprehensive approach results in ROI by optimizing material utilization, machine motion, manpower, and data management.

Motion : Faster cutting times to increase capacity and efficieny

Material : Smart nesting saves 4% average on new and remnant use

Machines : Central control gives you more flexibility and simplicity

Manage : Integrate operational data for better insight and control

Manpower : Faster programming and automation to empower your team

Versatile CAD Import

Smart time-saving CAD import recognizes 2D parts or 3D assemblies, and automatically calculates part cost and cutting time

Train

Diverse CAD Import

SigmaNEST software directly imports any major 2D and 3D file for painless part creation

Leverage filters and mapping tools to only bring in the parts you need

Recognize important CAM features on the drawing or model like bevels, milling pockets, and bends

Automatic error correction for DXF, DWG, CDL, IGES, DSTV, STEP files, G-code and NC ESSI code

SigmaNEST_PartCreate

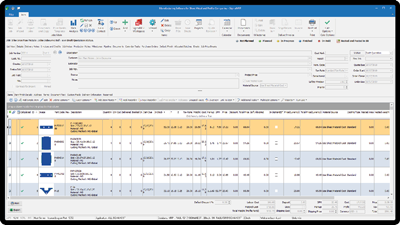

Part Creation and Version Management

Fast geometry creation with easy CAD tools, standard shapes library, user-definable scripting, dimensioning, and part data marking

Store part, nest layout, toolpath, and machine data in an intelligent workspace file

Integrated parts database keeps a searchable catalog of all parts, and part geometry, material, area, weight, and cost

SigmaNEST software automatically calculates part area, weight, cutting time, cost, and material requirements on import

User-definable reports and cost parameters

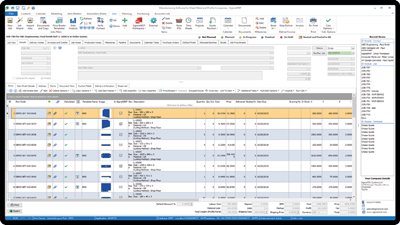

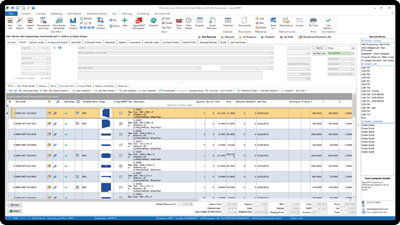

Accelerate Business with SigmaNEST

Streamline business with instant quoting, automated work orders and BOMs, job tracking, scheduling and integrated production data

Track status of each part for every order

Dynamically load multiple orders for just-in-time nesting and cutting

Explicit control for holding and releasing orders and parts for production

Integrated order database

SigmaMRP_item_masters

SigmaNEST has dozens of pre-built report templates for different business areas like costing, inventory, machine operations, and unloading

Easy-to-use editor to customize any report

SigmaNEST reporting data can be imported, exported, or connected to nearly any system

SigmaNEST Advanced Motion

SigmaNEST is one programming software for all simple and complex machines – including punch, profile, and combination

SigmaNEST intelligent tool path

Sophisticated Toolpath Strategies

SigmaNEST utilizes state-of-the-art machine motion options that reduce cutting time, consumable usage, and tool wear

Optimum default settings for machine, material, and thickness simplify programming choices and reduce trial and error

Increase machine performance with improved sequencing, scrap stability analysis, machine bed slat detection, and more

SigmaNEST provides 3D modeling for accurate bevel programming to ensure part quality

Recess tabs to eliminate grinding, automatic center-of-gravity tabs to avoid tipping

Common line cutting, bridge cutting, and chain cutting reduce cut distance, z-axis head movement, and pierce quantity

Pre-Pierce using secondary processes such as drill and punch to limit consumable wear and improve quality

BHQ bolt hole quality for plasma cutting

Automatic crop cut and scrap cut for safe processing and removal of excess material

SigmaNEST For Any Machine

Above all SigmaNEST empowers you to operate your shop, your way by letting you select the solution you need

SigmaNEST for Punch and Combination

SigmaNEST offers comprehensive nesting with powerful sequencing that provides ultimate control of laser/punch combination machines

Formed feature protection saves forms by reorganizing the nearby hits on parts

Stored pattern punching automatically punches production parts consistently

SigmaNEST front nest

SigmaNEST for Waterjet Cutting

SigmaNEST’s advanced programming optimizes feed and flow rate for superior part quality and maximum cutting speed

SigmaNEST Router pocketing

SigmaNEST for Router and Drilling

Advanced router and drilling solutions with automatic recognition of complex 3D models

for safe and easy toolpath application

Integrated Data

Integrate data from all areas of your operation to gain key insights and run more smoothly

SigmaNEST provides full integration and automatic part creation with 2D and 3D CAD systems including SolidWorks Enterprise PDM

Smart inventory management with stock control and remnant tracking

Complete part quoting, cost estimation, and searchable part database

SigmaSUITE products integrate with shop floor controls through Color Offload, Load Manager and Shop Floor Data Capture

Advanced solutions for greater automation from shop floor optimization

SigmaNEST integrates with ERP/MRP business systems for cost control and profitability

SimTrans data translation integrates production processes with business operations

Total integration with SigmaMRP for streamlined costing, planning, and tracking