Product Overview

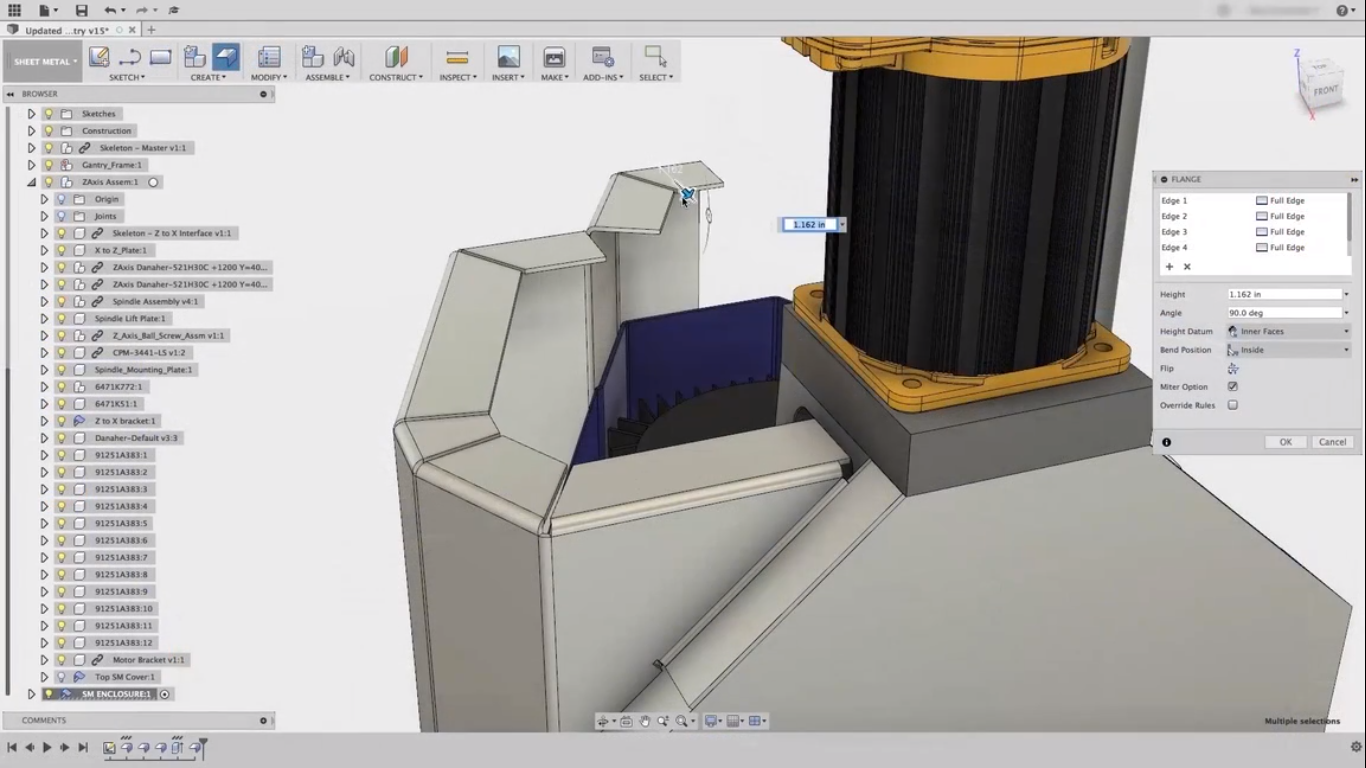

Autodesk Fusion 360® with PowerInspect® is 3D measurement software for offline programming of inspection routines that monitor and control manufacturing processes.

Inspect, validate, and manage quality of all measurement equipment.

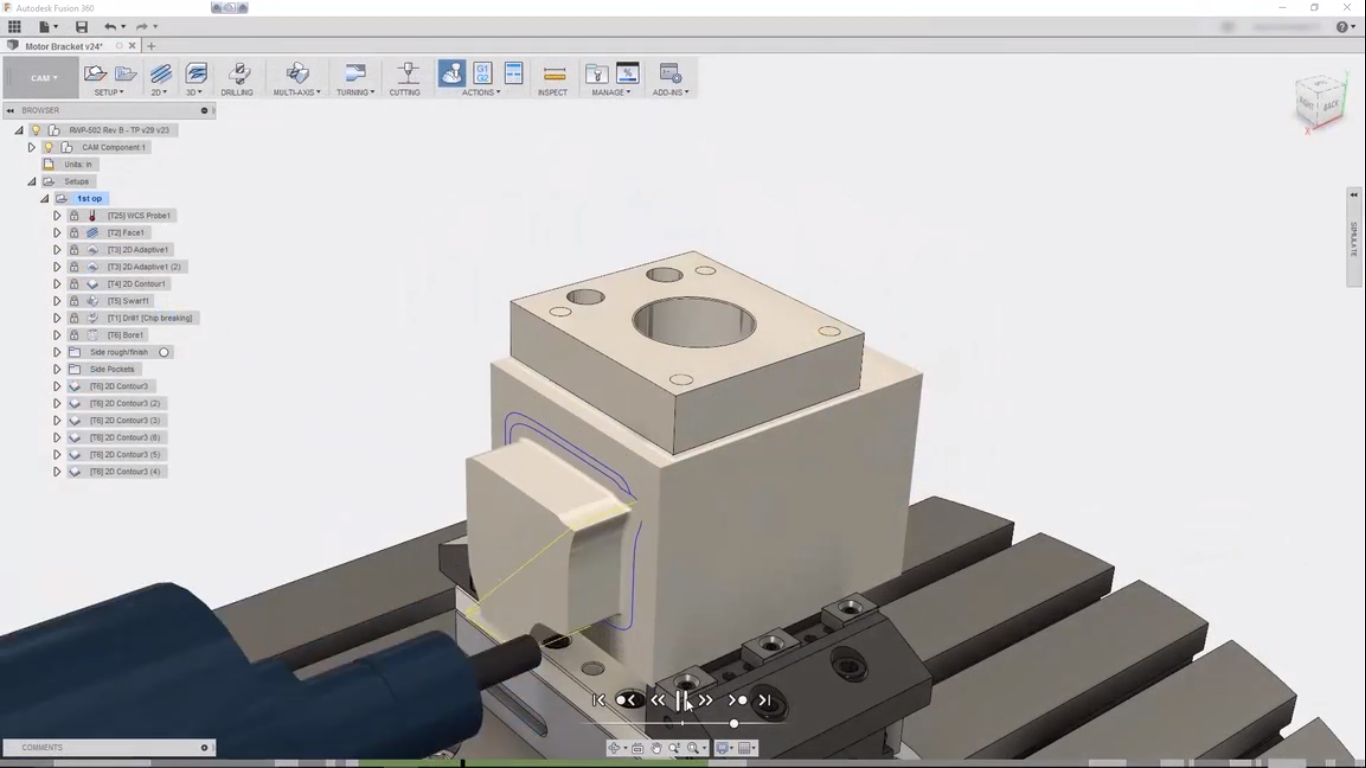

Use on-machine verification to measure parts during production.

Now includes Fusion 360, Fusion 360 Team, and Fusion 360 Machining Extension

Specifications

Increase part quality

Use in-process inspection to control your manufacturing process and avoid non-conformance.

Speed up production times

Replace labor intensive manual processes with automated workflows to complete projects faster.

Avoid production bottlenecks

Use on-machine verification on the shop floor to free up the quality control team.

Support for multi-devices

Use measuring equipment, including CNC CMMs, from a range of hardware providers

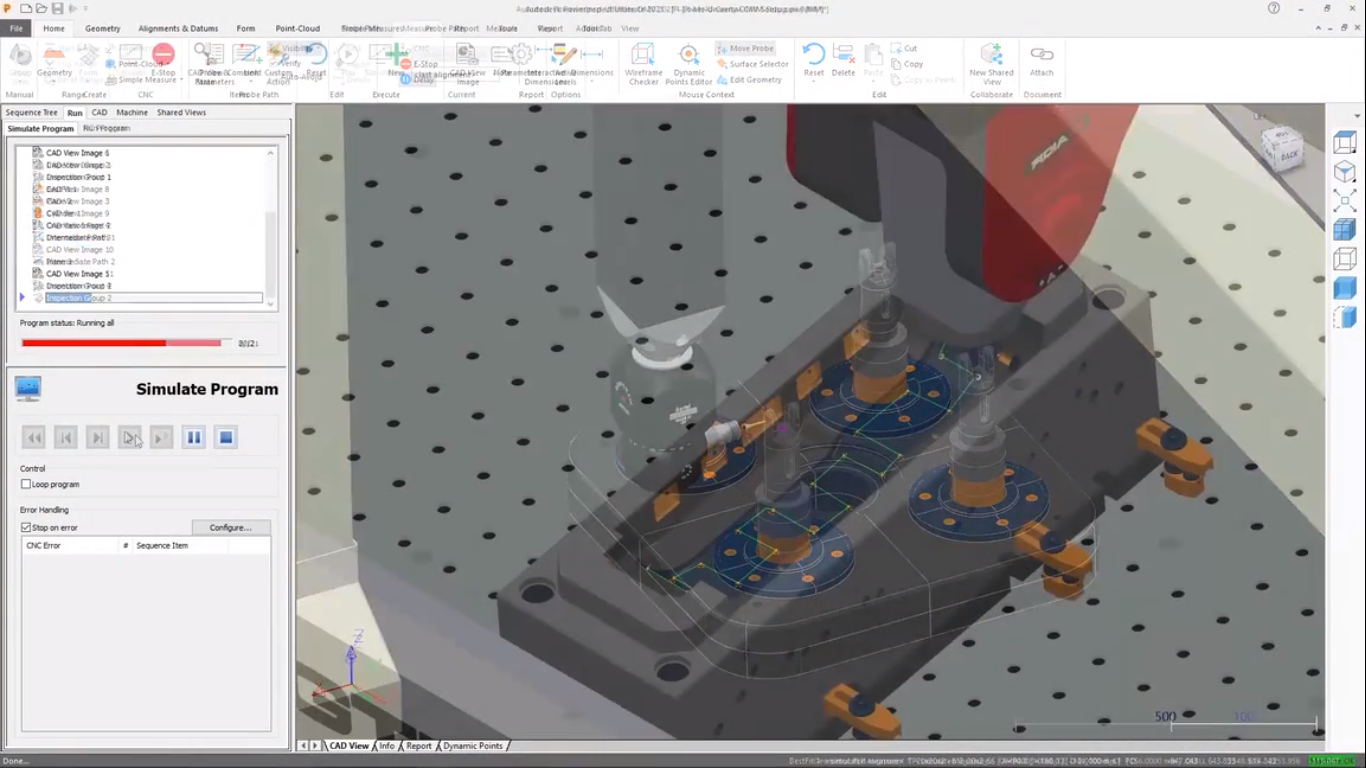

Automated inspection

Use automated inspection devices such as CNC/DCC CMMs and machine tool probing

Manual inspection

Use one interface for all your portable inspection devices, including manual CMMs, inspection arms, and more

Complex shape inspection

Apply the best strategies to inspect complex shapes. Automatically compile results into reports

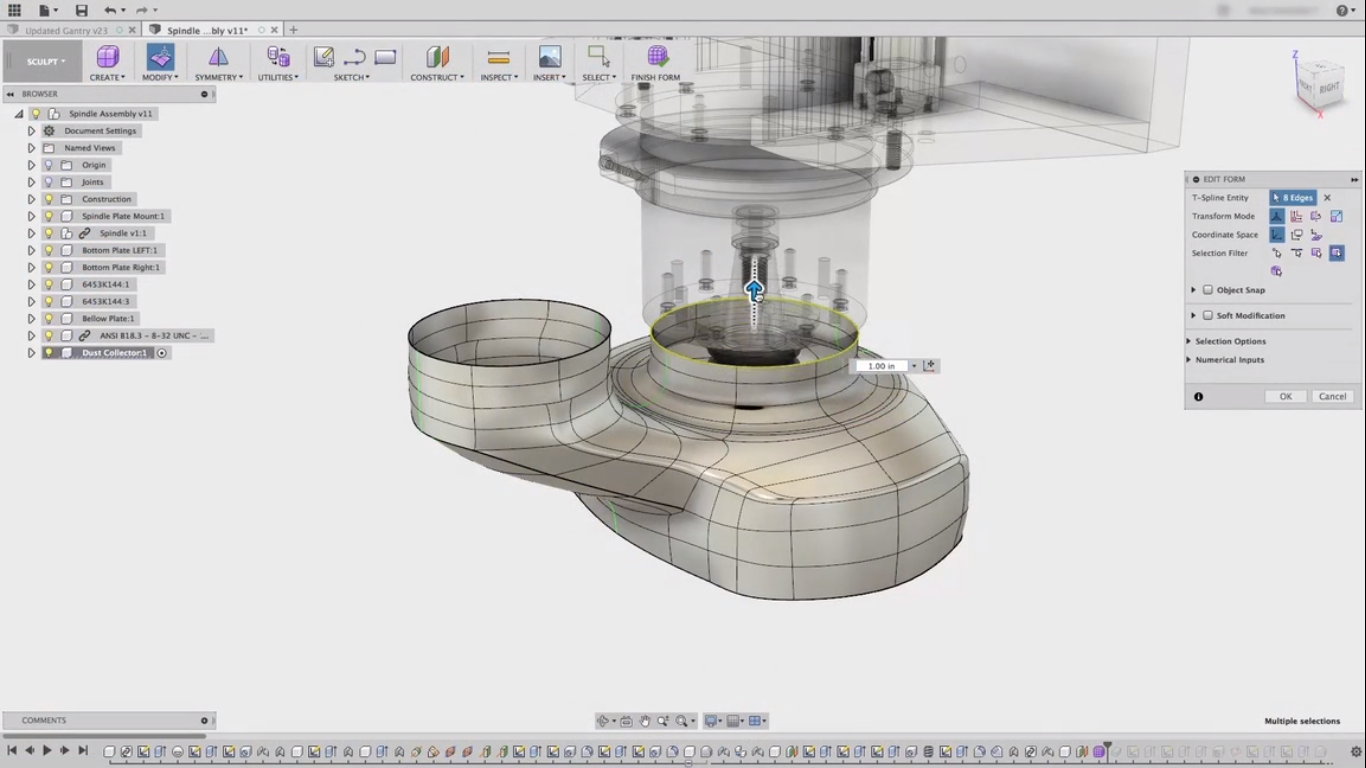

Graphical programming

Explore easy programming for measurement sequences. Measure parts with minimal preparation

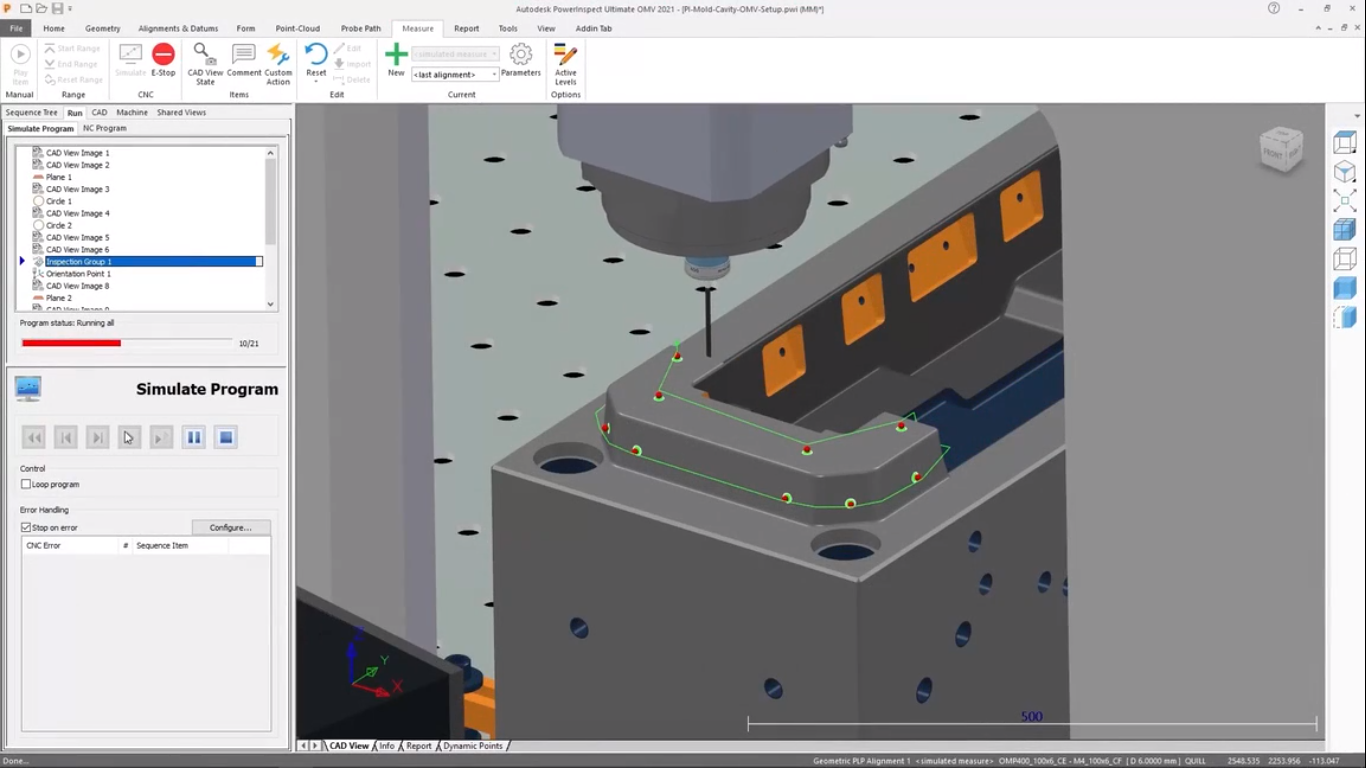

Automatic machine collision checking

Minimize chances of collisions during automated inspections. Simulate measurement sequences offline

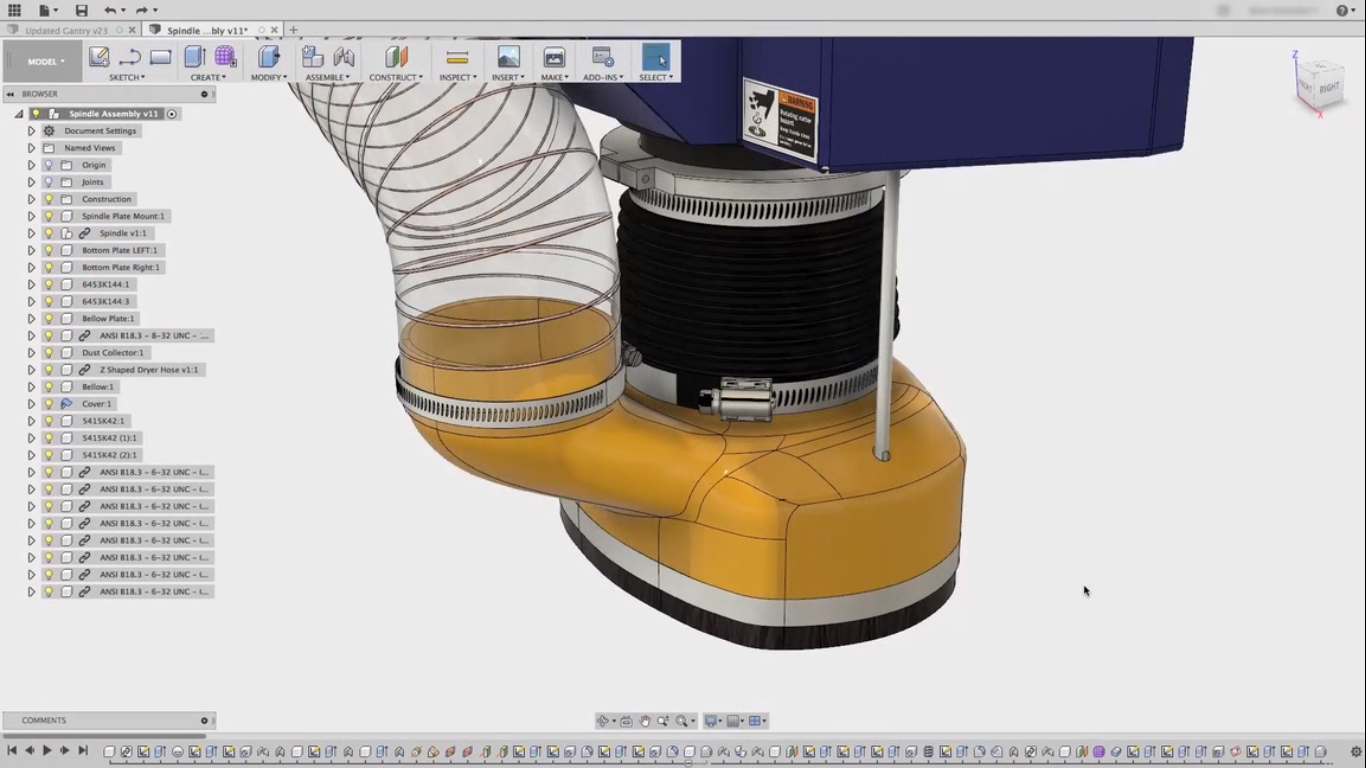

Manufacturing integration

Optimize manufacturing with adaptive fixturing, on machine verification (OMV), electrode inspection, and clay milling

Guided lines

Save time and avoid confusion when trying to locate an inspection point within a large session

2D features from point clouds

Automatically fit 2D features from point cloud data and have confidence in measurement results